How many times as a kid did you hear your mom yell, “Get what you need and shut the fridge door already!” Well, turns out that mom was right, studies have showed that refrigerator door openings account for 7% of fridge energy use. Now, think of that number with a walk-in refrigerator that’s average cubic feet is easily more than twice the size of a home refrigerator (yikes, that’s a lot of energy wasted), and what if that same walk-in refrigerator was accidentally left open all night. Now we’re looking at an entirely different type of loss: lost energy and lost food.

How many times as a kid did you hear your mom yell, “Get what you need and shut the fridge door already!” Well, turns out that mom was right, studies have showed that refrigerator door openings account for 7% of fridge energy use. Now, think of that number with a walk-in refrigerator that’s average cubic feet is easily more than twice the size of a home refrigerator (yikes, that’s a lot of energy wasted), and what if that same walk-in refrigerator was accidentally left open all night. Now we’re looking at an entirely different type of loss: lost energy and lost food.

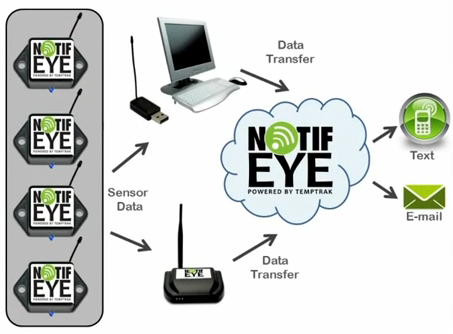

But accidents like this can be prevented. Cloud-based monitoring systems are quickly changing how restaurant and food service owners are able to accurately monitor temperatures.

What is It?

Cloud-based monitoring essentially means that information is sent wirelessly from sensors to an online system, and that information can be accessed from anywhere in the world, as long as you have a computer, tablet, or smartphone. The information that can be sent is limitless, and is used in many different ways.

For cloud-based temperature monitoring systems, like NotifEye or this HACCP Touch Data Recorder from Comark, the information being sent is temperature degrees ranging from -40⁰ to 257⁰F. Sensors are placed in different locations (wet or dry locations) throughout the food service establishment and they gather temperature readings that are then sent to a secure online system. The data sent over can be viewed anytime of the day, but even more importantly the software monitors the readings and will alert you when a temperature is off, like the refrigerator door being left open, the fryer not keeping oil hot enough, the holding case losing temperature, etc. Notifications can be sent to you via email or text.

What Kind of Temperatures Could I Monitor?

It’s up to you. The standards are walk-in refrigerators, freezers, ice machines, and dry storage area, but we found uses for temperature monitoring in just about every area of the restaurant. What if the heater was set way too high in the dining room and blasting 90⁰F all night? You could walk in the next day and find out about it, or you could be notified about it as soon as readings are gathered.

Why is it so Important?

There are multiple reasons why it’s important to monitor temperatures on a regular basis. Every year there are thousands of businesses in the food service industry that lose valuable inventory or get fined by the local health department because temperatures are inadequate. Monitoring temperatures ensures that equipment is running how it should, and saves your business from potential risks.

It helps prevent health violations and harm to your customers, and it helps save your business.

Is it Pricey?

All cloud-based temperature monitoring systems are priced differently, but we’ve seen plenty that are very reasonably priced. Many restaurant owners that have installed the systems have reported return on investment in less than two years. And since temperature monitoring seems to be one of the core values in the 7 steps of HACCP, we see it as an investment that could save your business one day.

What Are The 7 Steps of HACCP?

Glad you asked, HACCP (Hazard Analysis Critical Control Point) is a list of seven recommended food safety rules originally written for NASA, but has since been adopted in the food service industry by the FDA and USDA. The 7 steps are:

- Conduct a Hazard Analysis. The hazards are grouped into 3 categories: biological, chemical, and physical.

- Identify the critical control points, including cross-contamination, cooking, cooling, and hygiene.

- Set up actions to ensure safety is maintained at all of the critical control points defined.

- Establish monitoring procedures for the critical control points, and make sure to use the right signs, tools and training materials to make sure they are monitored accurately.

- Establish corrective actions for the critical control points.

- Set-up recordkeeping procedures to log information, like with flowcharts and temperature checks.

- Verify that the system put in place is working: validation, ongoing verification, and reassessment.

By the way, HACCP is pronounced “hassip.”

Corner Booth Blog | TundraFMP Restaurant Supply, News & Equipment Blog

Corner Booth Blog | TundraFMP Restaurant Supply, News & Equipment Blog

hi i would like to enquire the prices for your notifeye product

Hi Peter,

You can check out our NotifEye products here: https://www.etundra.com/cooper-atkins/health-supplies-food-safety/food-safety-supplies/kitchen-thermometers/data-loggers/

– Tundra Team