Restaurants always have a large amount of inventory to deal with. Figuring out where to store this inventory while it awaits its turn on the cooking line can be a major headache. One of your primary weapons in the storage battle is wire shelving. Shelving units can be built to fit just about any space in your restaurant, and more than likely you’ve got some pretty odd-shaped areas you use for dry or cool storage.

The most important decision you need to make when buying wire shelving is which type to use in different locations and situations in your restaurant. That’s because different types of shelving will perform better in different situations. For example:

Plated wire shelving is chrome plated. It’s rust resistant and can handle up to 150 pounds per shelf. Plated shelving is perfect for dry storage situations. It’s affordable, durable, and can be fit with a caster set for easy mobility. The one place plated wire shelving should NOT be used is in a walk in cooler. This is because plated shelving is rust resistant, but it’s not rust proof. As you already know, walk ins are a very moist environment. It won’t be long before your walk in shelving is coated with rust. Health inspectors tend to frown on that situation because rust particulates inevitably end up in food product.

Now I can’t tell you how many restaurant walk ins I have seen filled with plated wire shelving. The basic fact is that plated shelving is less expensive than the alternative, at least initially. But over time you’ll end up buying two or even three plated shelving sets for your walk in as opposed to one set of epoxy coated shelves, and you’ll be covering an important food safety issue at the same time.

Epoxy coated wire shelving is pretty self-explanatory: it’s wire shelving with an epoxy coat on it. This shelving is rust proof, making it the essential shelving for use in walk ins. It is more expensive than plated shelving, but as I’ve already said, that will probably work itself out over time. The epoxy coating has been known to wear off over time, especially on shelves that have a lot of metal (cold pans, etc.) sliding around, but these individual shelves can be replaced pretty easily.

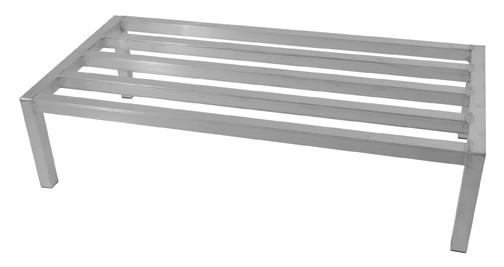

Both plated and epoxy shelving can handle about 150 pounds of stuff before they start to warp and bend. If you need to store heavier items (like sacks of rice or potatoes), you need to go to a heavier hitter.  Dunnage racks are perfect for this application. These are 12” – 16” tall heavy duty shelves that are kind of built like a long foot stool. They can handle a LOT of weight: up to 2,000 pounds in most cases. They can also plug into your existing wire shelving system pretty easily: just leave out the bottom shelf and slide the dunnage rack in underneath. The two most common materials used are plastic and aluminum, both good anti-rust materials, although I imagine plastic is a little better.

Dunnage racks are perfect for this application. These are 12” – 16” tall heavy duty shelves that are kind of built like a long foot stool. They can handle a LOT of weight: up to 2,000 pounds in most cases. They can also plug into your existing wire shelving system pretty easily: just leave out the bottom shelf and slide the dunnage rack in underneath. The two most common materials used are plastic and aluminum, both good anti-rust materials, although I imagine plastic is a little better.

Caster sets are also a key component to any wire shelving unit. That’s because sooner or later, you’re going to want to move shelves for cleaning. The other nice thing about casters is they give your bottom shelf some extra clearance off the floor, which health inspectors like. In general, you should always have 6” of clearance for cleaning under shelves, whether you’re in a walk in or in dry storage.

You’ll want expanding stem casters. These casters fit into the round or square posts on your shelving units and then expand out to make a tight fit. Also make sure two of the four casters have a brake so you can keep shelving from rolling around.

You need shelving to keep organized. Just make sure you use the right shelving for the right situations, and that will save you a lot of headache further down the line.

Corner Booth Blog | TundraFMP Restaurant Supply, News & Equipment Blog

Corner Booth Blog | TundraFMP Restaurant Supply, News & Equipment Blog

I had wire shelving in my previous kitchen and utterly hated them! Anything that wasn’t wide enough to simply span 3 wires had a habit to tumble over if not structured perfectly. And, whenever something did spill, it went all the way to the ground…making everything beneath it filthy and sticky on the way down! When we created our overflow pantry in the cellar, we put in wood shelving…I Love them and, when we get to it, our new corner kitchen will probably also have wood shelves.